Preliminary Treatment

Preliminary treatment of wastewater is a critical first step in the water treatment process, designed to prepare the inflow for subsequent treatment stages. This stage involves the removal of coarse solids and other large materials that could potentially cause damage to pumps and other treatment equipment. By doing so, it helps in protecting the intricate processes that follow, such as biological treatment and secondary clarification. A comprehensive preliminary treatment usually includes screening and grit removal alongside other processes such as comminution, which aids in breaking down large objects into smaller, more manageable pieces.

The importance of an effective preliminary treatment system cannot be overstated as it ensures the efficient operation of the subsequent treatment stages. It can also be adapted for industrial wastewater pre-treatment, adjusting to the varying nature of industrial effluents. Well-designed preliminary treatment is essential not only for maintaining the quality and performance of wastewater treatment plants but also for ensuring compliance with ever-evolving environmental regulations.

Key Takeaways

- Preliminary wastewater treatment is essential for removing coarse solids to protect subsequent treatment stages.

- It includes processes like screening, comminution, and grit removal to manage different waste materials.

- The design of preliminary treatment systems must accommodate diverse industrial effluents and regulatory standards.

Preliminary Treatment of Wastewater: Essentials for Efficient Process Flow

Preliminary treatment of wastewater is the first critical stage in the wastewater treatment process, laying the groundwork for further filtration and purification. It is designed to remove large and small objects that could impede subsequent treatment phases.

Purpose and Goals

The primary purpose of preliminary treatment is to prepare wastewater for subsequent treatment processes by removing coarse solids and other large materials. These initial steps are crucial as they prevent damage to downstream equipment and reduce the load on secondary treatment facilities.

Process Overview

Preliminary treatment involves several physical operations, primarily:

- Screening: Removal of large waste solids such as rags, sticks, and plastics. Screening is conducted using devices like bar racks and fine screens, which act as sieves to capture solid materials.

- Grit Removal: Sedimentation of inorganic solids, like sand and gravel, is achieved through grit chambers. Grit removal protects downstream processes from abrasion and deposition.

- Comminution: A process which grinds the larger solids that pass through the screens into smaller pieces, making the ensuing treatment stages more effective.

These treatments are the quintessential steps included in what is known as the preliminary treatment of wastewater and set the stage for primary, secondary, and tertiary treatments that follow.

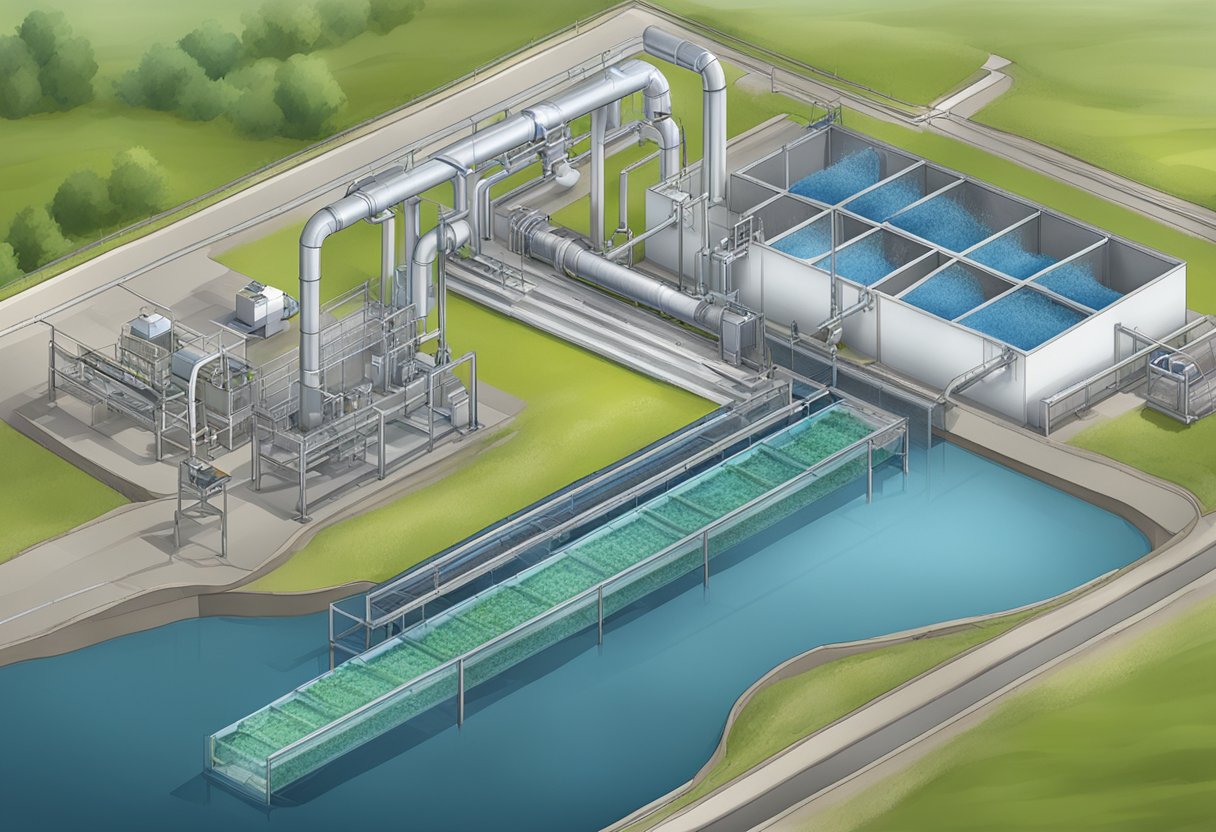

Screening

Screening is a crucial first step in the preliminary wastewater treatment process, designed to protect downstream equipment from large solids and various debris. Its efficiency impacts the performance and longevity of subsequent treatment stages.

Types of Screens

Multiple types of screens are utilized in wastewater treatment, each serving a distinct purpose. Manual screens require human effort for operation and are suitable for small or remote facilities. Mechanical screens, on the other hand, are automated, handling larger volumes efficiently. Examples include bar screens, where wastewater passes through bars spaced to allow the flow of water while capturing larger solids, and fine screens, which have smaller openings to catch finer particles.

Screening Equipment

Screening equipment is engineered to cope with diverse types of waste components. Coarse screens generally have openings over 6 mm and are the first line of defense. For finer particles, micro screens with openings as small as 1 mm are employed. The choice of equipment depends on factors such as flow rate, load debris, and downstream processes, with common types including rotary drums, step screens, and continuously cleaned bar screens.

Handling Screenings

The material captured by the screening process, known as screenings, requires careful handling. After removal, screenings are often washed to recover organic material and compacted to reduce volume, lowering disposal costs. Proper handling ensures that screenings do not contribute to odors or attract pests.

For a comprehensive look at screening in wastewater treatment, including maintenance and operation specifics, one can refer to resources like the U.S. Environmental Protection Agency’s webinar on Preliminary Wastewater Treatment. These screenings, if not properly managed, can lead to increased operational costs and environmental concerns.

Comminution

In the context of preliminary wastewater treatment, comminution refers to a process that grinds up solid waste in the water into smaller pieces. This mechanical treatment is essential as it prevents larger, solid matter from causing blockages or damaging the equipment in subsequent treatment stages.

Comminutors operate by using a combination of rotating blades or grinding mechanisms. As wastewater enters the comminution device, these blades effectively cut the solid materials, such as rags or plastic, into finer particles that can easily pass through the plant without hampering operations.

Key Benefits:

- Protects Downstream Equipment: By reducing the size of solid particles, comminution safeguards pipes, pumps, and other apparatus from clogging or damage.

- Improves Processing: Smaller particle size can enhance the effectiveness of subsequent treatment processes, like sedimentation and biological treatment.

Considerations:

- Maintenance: Comminutors require regular upkeep to maintain their functional integrity and efficiency.

- Operation: Proper operation ensures the efficacy of the process, reducing the likelihood of malfunction or breakdowns.

Through comminution, wastewater treatment plants ensure that larger solids are reduced to a manageable size, aiding the overall treatment process and efficiency. When integrated with other preliminary treatments such as screening and grit removal, these systems create a more consistent and controlled flow of wastewater, making it less taxing on facility infrastructure.

Grit Removal

In the preliminary wastewater treatment process, grit removal is critical for protecting downstream equipment from abrasion and minimizing deposit formation in channels and pipelines. Grit, primarily composed of sand, gravel, and other heavy materials, is removed to prevent excessive maintenance and ensure efficient treatment operations.

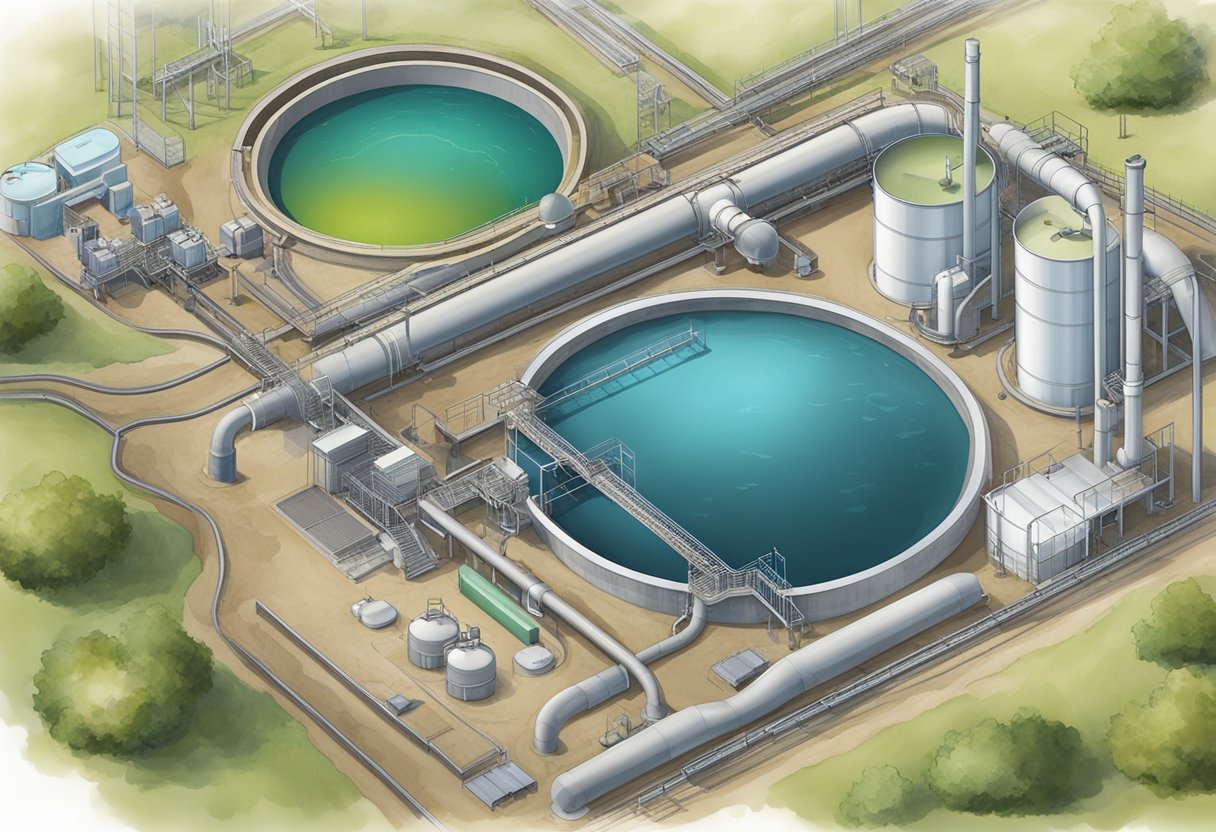

Grit Chambers

Grit chambers are specifically designed basins where the velocity of wastewater flow is controlled to allow grit to settle out while organic material continues in suspension. They are typically rectangular or circular in design and constructed to provide easy grit sedimentation and removal. This process is fundamental as it reduces the wear on mechanical equipment, maintains tank volume, and prevents the grit from overflowing into other treatment units.

Aerated Grit Chambers

Aerated grit chambers employ aeration to create a spiral flow pattern to separate grit from the wastewater stream effectively. Air is introduced at the bottom of the chamber, which allows for a selective settling. Organic materials remain in suspension due to the upward velocity of air bubbles, thereby improving grit settling. This process offers a higher level of grit removal efficiency compared to non-aerated systems.

Grit Handling and Disposal

Once separated from the wastewater, grit must be handled and disposed of appropriately. Grit handling involves washing to remove attached organic material, dewatering to reduce volume and weight for disposal, and sometimes storing before final disposal. Proper disposal methods prevent environmental contamination and comply with regulations. Grit is often taken to landfills, but it can also be used as landfill cover, road base construction material, or in other beneficial applications if it meets local standards for reuse.

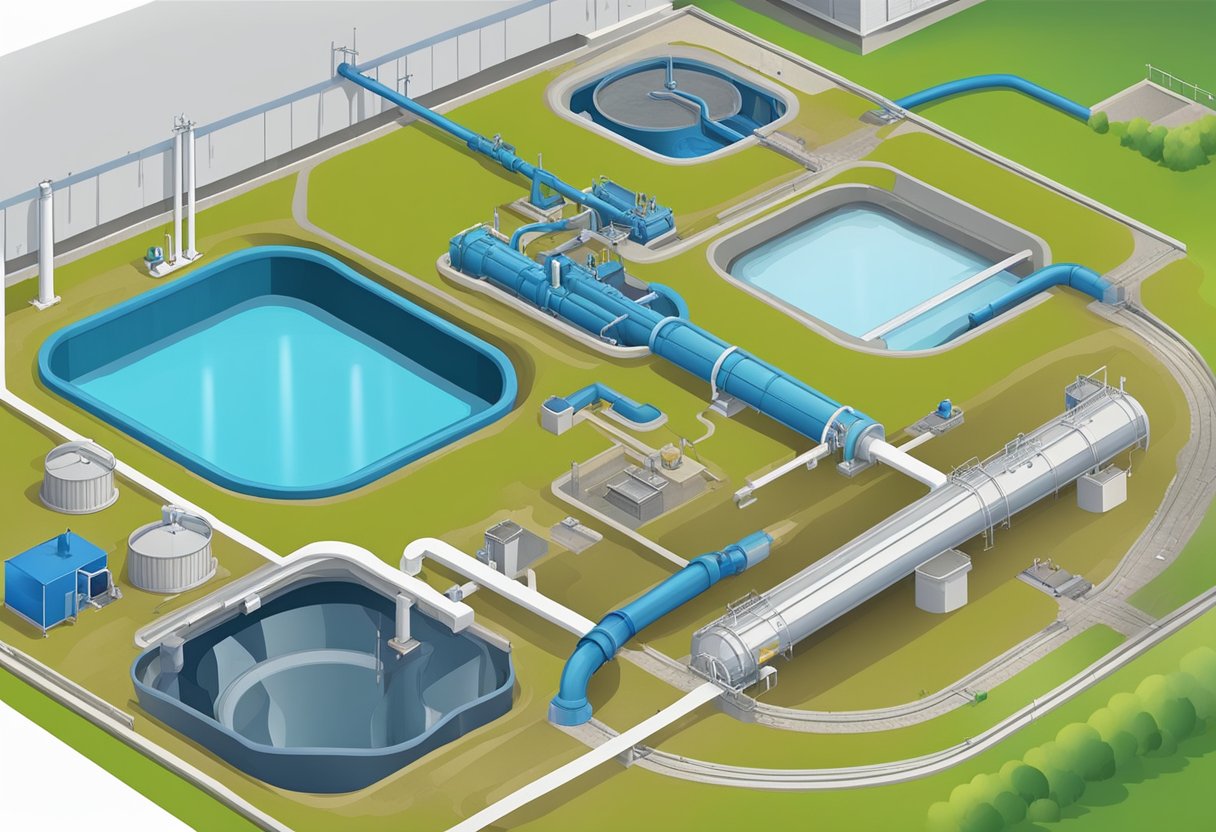

Pre-treatment for Industrial Wastewater

Industrial wastewater requires effective pre-treatment to protect both public health and the environment. Pre-treatment processes are designed to remove harmful materials before wastewater is discharged into municipal sewer systems. They typically involve physical, chemical, and biological steps aimed at eliminating pollutants that could otherwise damage sewer infrastructure or interfere with subsequent treatment stages.

Physical Pre-treatment Methods:

- Screening: Devices like bar screens and fine screens intercept solids like rags, sticks, and plastics.

- Sedimentation: This allows heavier particulate matter to settle out of the water column.

- Equalization Basins: These basins are used to dampen flow surges and facilitate uniform treatment.

Chemical Pre-treatment Options:

- Neutralization: For pH adjustment, either acids or alkalis may be added.

- Coagulation and Flocculation: These processes use chemicals to encourage the agglomeration of fine particles into larger ones that can be removed more easily.

Biological Pre-treatment Steps:

- Although less common as a preliminary measure, there are instances where certain biological treatments may take place to degrade organics.

Pre-treatment not only prevents potential damage to treatment facilities but also ensures compliance with regulatory standards for discharge. An effective industrial wastewater pretreatment program will outline the specific requirements and processes, which vary based on the industrial facility’s output and the composition of its wastewater.

Successful pre-treatment processes contribute significantly to the overall effectiveness of wastewater management and speak to the robustness of industrial responsibility in safeguarding water quality.

Design Considerations

When designing a system for the preliminary treatment of wastewater, engineers must assess critical factors such as the variable loads the facility will encounter and the types of equipment that will best handle these conditions. Durability and ease of access for maintenance are likewise pivotal aspects to ensure sustainable operation.

Hydraulic and Organic Loadings

- Hydraulic Loadings: It is crucial to calculate the peak flow rates to determine the size of channels, screens, and grit chambers. Design and Operational Considerations emphasize that facilities must accommodate variations in flow and load while avoiding overflows during storm events.

- Organic Loadings: Preliminary treatment processes are not primarily designed for organic removal, yet they are affected by the presence of organic materials. Engineers must estimate the average and peak organic loads to properly size equipment for efficient removal of debris and grit without compromising the subsequent treatment stages.

Equipment Selection

- Types of Screens: Selection of screens depends on the nature of the wastewater and the degree of material removal required. From coarse to fine screens, each serves a purpose to protect downstream processes. The choice of screens significantly determines the efficiency of the preliminary wastewater treatment.

- Grit Removal Systems: Grit chambers, whether horizontal flow, aerated, or other types, should be chosen based on the specific needs of the facility. The design must facilitate effective grit extraction to prevent abrasion and sedimentation in downstream equipment.

Maintainability and Accessibility

- Equipment Access: The design layout must provide ample space for operations staff to easily access equipment for inspection, maintenance, and repairs. This ensures that components such as screens and grit removal systems are readily reachable.

- Maintenance Planning: A system’s design should factor in the ease of equipment maintenance. For instance, mechanical screens and comminutors require regular servicing to remain operational. Thus, the inclusion of redundancies and the choice of durable materials are essential for long-term functionality.

Environmental and Regulatory Compliance

In preliminary wastewater treatment, compliance with environmental and regulatory standards is paramount. Facilities must adhere to guidelines established by entities such as the U.S. Environmental Protection Agency to ensure the protection of public health and the environment.

Key Components:

- Screening: To comply with regulations, facilities must effectively remove large solids through screening, which could otherwise damage equipment and hinder subsequent treatment stages.

- Grit Removal: Regulated removal of inorganic materials, such as sand, protects downstream processes from abrasion and sedimentation.

Regulatory Bodies:

- Federal: U.S. EPA

- State: Various state environmental agencies

- Local: Municipal wastewater treatment authorities

Compliance also involves meeting specified thresholds for removing objects and sediments in preliminary treatment. Regular inspections and monitoring are conducted to ensure adherence to prescribed effluent standards. Facilities may face penalties for non-compliance, including fines or sanctions.

Documentation is crucial. Facilities must maintain accurate records of operational parameters and incidents to demonstrate continuous compliance. This documentation may be subjected to audits by regulatory bodies to confirm that environmental protections are being adequately observed.

By strictly following these regulations, preliminary wastewater treatment operations play a critical role in preserving water quality and safeguarding ecosystems.

Future Trends in Preliminary Wastewater Treatment

The landscape of preliminary wastewater treatment is evolving as technologies advance. In the near future, the sector anticipates several promising trends aimed at enhancing efficiency and sustainability.

- Automation and Smart Screening: The integration of automation is set to rise. Smart screening technologies will utilize real-time monitoring to optimize the removal of large and small debris, thereby preventing mechanical issues downstream.

- Advanced Materials: Screens and other preliminary devices may employ advanced materials, which are more resistant to wear and corrosion. These materials will likely prolong the lifecycle of equipment and reduce maintenance requirements.

- Energy Efficiency: There will be an emphasis on reducing energy consumption within preliminary treatment facilities. This could involve the adoption of innovative designs that minimize the energy required for screening and grit removal.

- Resource Recovery: Preliminary treatment processes may start incorporating designs that facilitate the recovery of valuable resources, such as phosphorus from grit.

- Compact Designs: The need for more compact treatment systems is growing, particularly in urban settings. The industry may see more compact units that can handle larger volumes of wastewater relative to their size.

- Combination Systems: Units that combine several treatment stages into one may gain popularity. These systems can streamline wastewater treatment processes and offer substantial space savings.

Technologies like comminutors are expected to become more sophisticated, with improvements aimed at enhancing fine screening capabilities to protect downstream processes from operational problems.

It’s anticipated that future advancements will further solidify the critical role of preliminary treatment facilities in maintaining efficient and reliable wastewater treatment infrastructures.

Frequently Asked Questions

The preliminary stage of wastewater treatment is essential for safeguarding subsequent treatment phases, ensuring efficient operation by removing larger contaminants that can cause damage and operational challenges.

What are the main components involved in the preliminary stage of wastewater treatment?

In the preliminary stage of wastewater treatment, physical units like bar racks, coarse screens, fine screens, and comminutors are utilized to protect further treatment processes by removing large and small objects from the wastewater.

How does preliminary treatment differ from primary treatment in wastewater management?

Preliminary treatment is designed to remove large debris and protect equipment, while primary treatment typically refers to the settling out of suspended solids through sedimentation tanks or clarifiers, which is the next step in wastewater management.

How does preliminary treatment differ from secondary treatment in wastewater management?

Preliminary treatment in wastewater management involves physically removing large solids and debris from the wastewater, while secondary treatment focuses on biological processes to remove dissolved and suspended organic matter. Preliminary treatment acts as the first step in the treatment process, preparing the wastewater for further purification in the secondary treatment phase.

Can you provide examples of common equipment used during preliminary treatment of wastewater?

Common equipment used during the preliminary treatment includes bar racks, fine screens for filtering out debris, and grit chambers for separating sand and other small, heavy particles from the wastewater stream.

What are the objectives of using preliminary treatment before other stages in wastewater treatment?

Preliminary treatment aims to remove materials that could pose mechanical issues to downstream processes, reduce the load on secondary treatments, and increase the overall efficiency and lifespan of the wastewater treatment facility.

How does tertiary wastewater treatment build upon preliminary and primary treatments?

Tertiary treatment of wastewater builds upon the previous stages by further polishing the effluent to achieve higher quality water standards, often involving advanced techniques like filtration, nutrient removal, and disinfection, intended for more stringent environmental regulations.

What substances are typically removed during the preliminary treatment of wastewater?

During the preliminary treatment, substances such as rags, large solids, and materials that could cause clogging or mechanical issues are typically removed to prevent damage to downstream treatment equipment and processes.

The post Preliminary Treatment appeared first on Water and Wastewater.

Article Source : www.waterandwastewater.com/...